Electrical insulating mat Electrical Safety Rubber Mat

Isolation Floor Mat 2-3-4-5 mm 1000 V

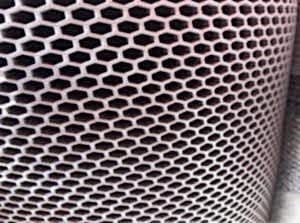

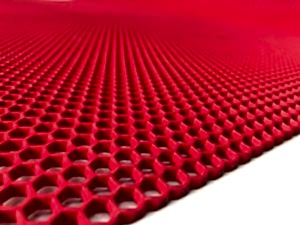

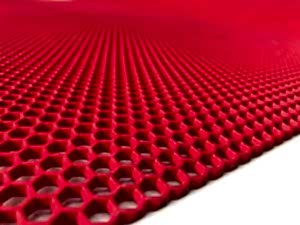

Insulated carpet mats—also known as dielectric floor mats or electrical insulation mats

What Are Insulated Carpet Mats?

Insulated carpet mats—also known as dielectric floor mats or electrical insulation mats—are designed to prevent electrical shock hazards in environments with active electrical equipment. They provide an essential protective layer between the floor and the human body, especially in high-voltage industrial or technical areas.

Benefits of Using Insulated Mats

Electrical insulation mats serve multiple purposes beyond just electrical protection. Key benefits include:

• Electrical shock protection up to 36kV (depending on class)

• Heat and sound insulation

• Improved workplace safety

• Anti-fatigue and ergonomic support

• Slip-resistant surface for stability

• Resistance to oil, acid, and chemicals (in industrial models)

Standard Insulation Mat Thickness Options

The thickness of insulation mats determines both their voltage resistance and durability. Below are the commonly available thicknesses:

Most Popular Insulation Mat Models by Material

Selecting the right insulation mat material is crucial for performance and safety. Below are the most commonly used materials and their characteristics

International Safety Standards for Insulated Mats

Ensuring your mat meets international electrical safety standards is essential. Key standards include:

IEC 61111:2009

• International standard for live working dielectric mats

• Specifies test voltages and insulation classes (Class 0 to Class 4)

ASTM D178

• U.S. standard for rubber insulating mats

• Details classification, thickness, and voltage breakdown resistance

IS 15652 (India)

• Standard for non-conductive mats for electrical purposes

• Often used in power generation and distribution sectors

Always look for certified products with proper labelling, voltage class marking, and test reports.

Application Areas of Insulated Mats

Insulated mats are used across many sectors. Some key areas include:

• Electric control rooms

• Substations and power plants

• Workshops and assembly lines

• Server rooms and data centers

• Factories with high-voltage machinery

• Laboratories and test benches

• Residential fuse boxes and panel boards